Seeding for CVD Films

Grow Defect-free, Wear-resistant Films with Nanodiamond Seeds

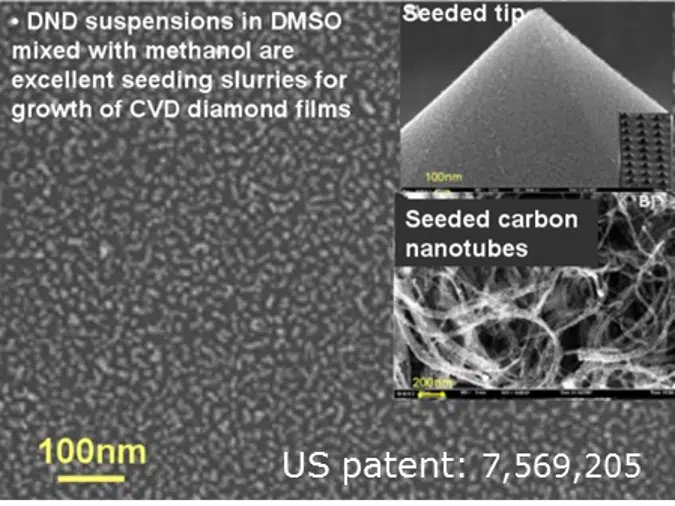

Chemical Vapor Deposition (CVD) growth of thin film diamond has an abundance of uses in the microelectronic and tooling industries because of the exceptional thermal conductivity and mechanical properties of diamond. In order to grow the highest quality films, diamond nuclei (“seeds”) need to be densely and uniformly distributed over a substrate. Adámas’s patented nanodiamond seeding slurries in Dimethyl Sulfoxide (DMSO) create a high density of nuclei required to grow dense, defect-free films of diamond on 2D and 3D substrates. DMSO-based slurries of nanodiamond provide highest resistance to agglomeration, important for formation of a uniform seeding layer.

Adamas offers three lines of seeding slurries: Blueseeds, Opalseeds, and Greyseeds, depending on the requirements for film growth. See individual descriptions below.

Various substrates seeded using detonation nanodiamond suspensions: a silicon wafer (2D substrate), a field tip array (3D), and nanodiamond coated carbon nanotubes.

Blueseeds for Nanocrystalline Film Growth

With primary particles of 4-5 nm size, Blueseeds are the smallest available diamond seeding crystals on the market. Use Blueseeds to grow films with the lowest roughness and highest wear-resistance, hardness, and corrosion-resistance. Slurries with spherical particles of 4-5 nm offer the highest seeding density for creating defect-free films for use in micro- and opto-electronics, tooling, biosensor and chemical sensor electrodes, and other applications where film quality is of the highest importance. Slurries are sold as 0.5% wt/volume nanodiamond in DMSO.

Opalseeds for Microcrystalline Film Growth

Opalseeds consist of tight aggregates of 4-5nm primary particles with aggregate sizes 20-30nm. Opalseeds are used for growth of high-quality microcrystalline films. Slurries are sold as 0.5% wt/volume nanodiamond in DMSO.

Grey seeds for Microcrystalline Film Growth

Greyseeds consist of tight aggregates of 4-5nm primary particles with aggregate sizes 50-60 nm. Greyseeds are used for growth of microcrystalline films. Slurries are sold as 0.5% wt/volume nanodiamond in DMSO.

Recommended Seeding Procedure:

(1) Preparation of Seeding suspension:

• 1 part of 5 mg/mL (0.5% w/v) seeding suspension is mixed with 3 parts of methanol. The mixture should be thoroughly mixed.

• (Optional) It is recommended that a probe tip ultrasonic horn is used to homogenize the mixture, though this is not required.

(2) Ultrasonic Seeding:

• After through cleaning of the substrate, it should be submerged into a solution of the seeding suspension such that at least 5 mm of the suspension is above the surface of the substrate. 15 minutes of ultrasonic treatment is sufficient for effective seeding.

(3) Preparation of Substrate:

• A standard cleaning process such as the SC1 or RCA clean process can be used to remove organic contaminants from the substrate.

(4) Post Seeding Rinse:

• After seeding, the substrate should be removed from the seeding suspension and ultrasonic bath, rinsed with methanol, and dried with inert gas or clean compressed air. The substrate is now ready for deposition growth of thin film diamond.